Super User

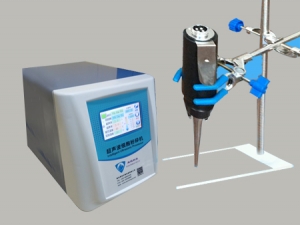

Ultrasonic Hand-Held Crusher | Disrupter | Disintegrator | Probe Sonicator (Touch Screen-ST Series)

Ultrasonic Hand-Held Crusher | Disrupter | Disintegrator | Probe Sonicator

(Touch Screen-ST Series)

Poduct DescriptiProduct Description

Product Description

The ST series hand-held ultrasonic cell crusher| disruptor with 4.3 TFT touch screen which is small in size and light in weight, is very suitable for micro experiments in laboratory. Automatic or manual mode is supported. Under the manual mode,the work and end time can be set up. The device is quite flexible and it's not limited by the space,so it's suitable for the processing with the experimental samples of little volume or mircro volume. The samples on the experinmental board can be processed quickly. The automatic mode is suitable for the experiment with big volume or for long time, which can be completed on the holder or inside the sound-proof enclosure.

Product Features

1. Automatic or manual mode is supported for option

2. Large TFT screen Display, Touch control for new version

3. 50 groups of experimental data can be set and stored, safe and convenient.

4. The ultrasonic power can be adjusted continuously, and the best experimental conditions can be explored.

5. The program has over-temperature/delay/fault protection settings and alarm system,which can protect the test samples to the maximum extent.

6. RS232 Interface is optional, which can support the data transmission between the PC and PLC to realize the remote control.

7. We provide the Sound-proof Chamber for standard configuration with perfect transportation.

Application

The instrument is widely used in the fields of biology, microbiology, physics, zoology, agronomy, pharmacy, petroleum, etc. It also can be used in Nanotechnology research such as the dispersion of nanomaterials (nanotubes, graphene, silica, etc.); sample homogenization and emulsification; accelerate dissolution, accelerate chemical reaction and other sample processing.

Technical Specification

|

Model |

BEST-250D |

BEST-400D |

|

Frequency |

20-25 |

20-25 |

|

(KHz) |

||

|

Power(W) |

0-250 |

0-400 |

|

Crushing Capacity |

0.1-150 |

0.1-300 |

|

(ml) |

||

|

Working Mode |

Automatic/ Manual |

Automatic/ Manual |

|

Voltage(V) |

220/110 |

220/110 |

|

Probe(mm) |

Φ3 |

Φ6 |

|

Probes Option(mm) |

Φ2、6、8 |

Φ2、3、8 |

|

Sample Temperature Protection(℃) |

0-99 |

0-99 |

Double Glassware for Ultrasonic Nano Material Dispersion

Double Glassware for Ultrasonic Naon Material Disperser

Description

Ultrasonic cell disruptor will produce certain thermal effect in the process of ultrasonic, the double glassware can realize internal cooling in the reaction system with the cooling water circulation system. It can avoid the sample's warming caused by the process of ultrasonic degeneration , and the effect is more convenient and outstanding relative to the traditional ice bath cooling method.

—GG17 high borosilicate material, resistant to high or low temperature, can work for a long time.

—Double layers design, cold water or hot water can achieve the internal temperature of the system.

—The top and bottom of the glassware is provided with an inlet and outlet.

—Various specifications are available.

Options

|

Volume (ml) |

50 |

100 |

250 |

500 |

1000 |

1500 |

or for the large opening visible glass is

Options

Probes for Ultrasonic Processor | Nano Material Dispersion

Probes for Ultrasonic Nano Material Disperser

Description

Probes (sometimes referred to as horns) are one-half wavelength long tools that act as mechanical transformers to increase the amplitude of vibration generated by the converter. They consist of two sections each having different cross-sectional areas.

The greater the mass ratio between the upper section and the lower section, the greater the amplification factor, and the greater the peak-to-peak excursion at the tip of the probe. Probes with smaller tip diameters produce greater intensity of cavitation, but the energy released is restricted to a narrower, more concentrated field. Conversely, probes with larger tip diameters produce less intensity, but the energy is released over a greater area. The larger the tip diameter, the larger the volume that can be processed, but at lower intensity. High gain probes produce higher intensity than standard probes of the same diameter, and are usually recommended for processing difficult applications.

Probes are fabricated from high grade titanium alloy Ti-6Al-4V because of its high tensile strength, good acoustical properties at ultrasonic frequencies, high resistance to corrosion, low toxicity, and excellent resistance to cavitation erosion.

Probe Option

|

Model |

Inch |

Frequency |

Power Range |

Crushing Capacity |

|

Φ2 |

1/12″ |

20-25KHz |

min-150W |

0.2-5ml |

|

Φ3 |

1/8″ |

20-25KHz |

min-250W |

3-10ml |

|

Φ6 |

1/4″ |

20-25KHz |

20-400W |

10-100ml |

|

Φ10 |

5/12″ |

20-25KHz |

100-600W |

30-300ml |

|

Φ12 |

1/2″ |

20-25KHz |

200-900W |

50-500ml |

|

Φ15 |

5/8″ |

20-25KHz |

300-1000W |

100-600ml |

|

Φ20 |

4/5″ |

19.5-20.5KHz |

400-1100W |

100-1000ml |

|

Φ22 |

5/6″ |

19.5-20.5KHz |

400-1100W |

200-1000ml |

|

Φ25 |

1″ |

19.5-20.5KHz |

800-1500W |

500-1200ml |

Sound-proof Chamber | Sound Abating Enclosure for Ultrasonic Nano material Dispersion

Sound-proof Chamber | Sound Abating Enclosure for Ultrasonic Nano Material Dispersion

Description

Even though ultrasonic vibrations are above the human audible range, ultrasonic processing produces a high pitched noise in the form of harmonics which emanate from the vessel walls and the fluid surface. The sound-proof chamber/enclosure permits extended processing without discomfort by reducing the sound by 35db which can effectively reduce the noise emitted from the ultrasonic processor.

The transparent access door permits observation during treatment and protects the operator against accidental splashing. A lifting platform is supported and can quickly adjust the samples. Otherwise large size enclousure can be customized according to customer requirements, with the function of automatic lifting, lighting and sterilization.

Specification

|

Outside (H x W x D) |

Inside (H x W x D) |

|

|

Dimensions |

22” x 14” x14” (550*350*350 mm) |

19” x 11.4” x11” (490*290*280 mm) |

|

Gross Weight |

10 KG |

|

|

Net Weight |

8 KG |

|

Sound-proof Chamber | Sound Abating Enclosure for Ultrasonic Graphene Disperser

Sound-proof Chamber | Sound Abating Enclosure for Ultrasonic Graphene Disperser

Description

Even though ultrasonic vibrations are above the human audible range, ultrasonic processing produces a high pitched noise in the form of harmonics which emanate from the vessel walls and the fluid surface. The sound-proof chamber/enclosure permits extended processing without discomfort by reducing the sound by 35db which can effectively reduce the noise emitted from the ultrasonic processor.

The transparent access door permits observation during treatment and protects the operator against accidental splashing. A lifting platform is supported and can quickly adjust the samples. Otherwise large size enclousure can be customized according to customer requirements, with the function of automatic lifting, lighting and sterilization.

Specification

|

Outside (H x W x D) |

Inside (H x W x D) |

|

|

Dimensions |

22” x 14” x14” (550*350*350 mm) |

19” x 11.4” x11” (490*290*280 mm) |

|

Gross Weight |

10 KG |

|

|

Net Weight |

8 KG |

|

Probes for Ultrasonic Processor | Graphene Disperser

Probes for Ultrasonic Graphene Disperser

Description

Probes (sometimes referred to as horns) are one-half wavelength long tools that act as mechanical transformers to increase the amplitude of vibration generated by the converter. They consist of two sections each having different cross-sectional areas.

The greater the mass ratio between the upper section and the lower section, the greater the amplification factor, and the greater the peak-to-peak excursion at the tip of the probe. Probes with smaller tip diameters produce greater intensity of cavitation, but the energy released is restricted to a narrower, more concentrated field. Conversely, probes with larger tip diameters produce less intensity, but the energy is released over a greater area. The larger the tip diameter, the larger the volume that can be processed, but at lower intensity. High gain probes produce higher intensity than standard probes of the same diameter, and are usually recommended for processing difficult applications.

Probes are fabricated from high grade titanium alloy Ti-6Al-4V because of its high tensile strength, good acoustical properties at ultrasonic frequencies, high resistance to corrosion, low toxicity, and excellent resistance to cavitation erosion.

Probe Option

|

Model |

Inch |

Frequency |

Power Range |

Crushing Capacity |

|

Φ2 |

1/12″ |

20-25KHz |

min-150W |

0.2-5ml |

|

Φ3 |

1/8″ |

20-25KHz |

min-250W |

3-10ml |

|

Φ6 |

1/4″ |

20-25KHz |

20-400W |

10-100ml |

|

Φ10 |

5/12″ |

20-25KHz |

100-600W |

30-300ml |

|

Φ12 |

1/2″ |

20-25KHz |

200-900W |

50-500ml |

|

Φ15 |

5/8″ |

20-25KHz |

300-1000W |

100-600ml |

|

Φ20 |

4/5″ |

19.5-20.5KHz |

400-1100W |

100-1000ml |

|

Φ22 |

5/6″ |

19.5-20.5KHz |

400-1100W |

200-1000ml |

|

Φ25 |

1″ |

19.5-20.5KHz |

800-1500W |

500-1200ml |

Double Glassware for Ultrasonic Graphene Disperser

Double Glassware for Ultrasonic Graphene Disperser

Description

Ultrasonic cell disruptor will produce certain thermal effect in the process of ultrasonic, the double glassware can realize internal cooling in the reaction system with the cooling water circulation system. It can avoid the sample's warming caused by the process of ultrasonic degeneration , and the effect is more convenient and outstanding relative to the traditional ice bath cooling method.

—GG17 high borosilicate material, resistant to high or low temperature, can work for a long time.

—Double layers design, cold water or hot water can achieve the internal temperature of the system.

—The top and bottom of the glassware is provided with an inlet and outlet.

—Various specifications are available.

Options

|

Volume (ml) |

50 |

100 |

250 |

500 |

1000 |

1500 |

or for the large opening visible glass is

Options

Double Glassware for Ultrasonic Processor | Cell Crusher | Homogenizer for Disruption

Double Glassware for Ultrasonic Processor | Cell Crusher | Homogenizer for Disruption

Description

Ultrasonic cell disruptor will produce certain thermal effect in the process of ultrasonic, the double glassware can realize internal cooling in the reaction system with the cooling water circulation system. It can avoid the sample's warming caused by the process of ultrasonic degeneration , and the effect is more convenient and outstanding relative to the traditional ice bath cooling method.

—GG17 high borosilicate material, resistant to high or low temperature, can work for a long time.

—Double jackets design, cold water or hot water can achieve the internal temperature of the system.

—The top and bottom of the glassware is provided with an inlet and outlet.

—Various specifications are available.

Options

|

Volume (ml) |

50 |

100 |

250 |

500 |

1000 |

1500 |

or for the large opening visible glass is

Options

Probes for Ultrasonic Processor | Cell Crusher | Homogenizer for Disruption

Probes for Ultrasonic Processor | Cell Crusher | Homogenizer for Disruption

Description

Probes (sometimes referred to as horns) are one-half wavelength long tools that act as mechanical transformers to increase the amplitude of vibration generated by the converter. They consist of two sections each having different cross-sectional areas.

The greater the mass ratio between the upper section and the lower section, the greater the amplification factor, and the greater the peak-to-peak excursion at the tip of the probe. Probes with smaller tip diameters produce greater intensity of cavitation, but the energy released is restricted to a narrower, more concentrated field. Conversely, probes with larger tip diameters produce less intensity, but the energy is released over a greater area. The larger the tip diameter, the larger the volume that can be processed, but at lower intensity. High gain probes produce higher intensity than standard probes of the same diameter, and are usually recommended for processing difficult applications.

Probes are fabricated from high grade titanium alloy Ti-6Al-4V because of its high tensile strength, good acoustical properties at ultrasonic frequencies, high resistance to corrosion, low toxicity, and excellent resistance to cavitation erosion.

Probe Option

|

Model |

Inch |

Frequency |

Power Range |

Crushing Capacity |

|

Φ2 |

1/12″ |

20-25KHz |

min-150W |

0.2-5ml |

|

Φ3 |

1/8″ |

20-25KHz |

min-250W |

3-10ml |

|

Φ6 |

1/4″ |

20-25KHz |

20-400W |

10-100ml |

|

Φ10 |

5/12″ |

20-25KHz |

100-600W |

30-300ml |

|

Φ12 |

1/2″ |

20-25KHz |

200-900W |

50-500ml |

|

Φ15 |

5/8″ |

20-25KHz |

300-1000W |

100-600ml |

|

Φ20 |

4/5″ |

19.5-20.5KHz |

400-1100W |

100-1000ml |

|

Φ22 |

5/6″ |

19.5-20.5KHz |

400-1100W |

200-1000ml |

|

Φ25 |

1″ |

19.5-20.5KHz |

800-1500W |

500-1200ml |

Sound-proof Chamber | Sound Abating Enclosure for Ultrasonic Processor

Sound-proof Chamber | Sound Abating Enclosure for Ultrasonic Processor

Description

Even though ultrasonic vibrations are above the human audible range, ultrasonic processing produces a high pitched noise in the form of harmonics which emanate from the vessel walls and the fluid surface. The sound-proof chamber/enclosure permits extended processing without discomfort by reducing the sound by 35db which can effectively reduce the noise emitted from the ultrasonic processor.

The transparent access door permits observation during treatment and protects the operator against accidental splashing. A lifting platform is supported and can quickly adjust the samples. Otherwise large size enclousure can be customized according to customer requirements, with the function of automatic lifting, lighting and sterilization.

Specification

|

Outside (H x W x D) |

Inside (H x W x D) |

|

|

Dimensions |

22” x 14” x14” (550*350*350 mm) |

19” x 11.4” x11” (490*290*280 mm) |

|

Gross Weight |

10 KG |

|

|

Net Weight |

8 KG |

|