Super User

BE Modbus to Digital Input I/O Modules Sector Won Project in India

BE(Bueno Electric) Remote I/O module sector won the BAS project in India.Confined by the contract,BE would supply 300 units of Modbus to I/O modules for Indian contractor within 2016. This is a breakthrough for BE to enter Indian BAS market.Modbus to I/O modules is an important product among BE products line,the product is worked out independently by BE R & D team, the series of products have the most advanced function in the world. It's more and more applied in important projects in the world. It will break the balance and monoploy of old giant brands.

Low Cost Economical GPS NTP Time Server

The Synch(BE-M-1-NTP) Industrial Grade GPS Network Time Server that we manufactured are specifically for electric power system, automatizatio system, telecom system,CCTV and traffic system that need high-precise time requirer.Our system is based on GPS, and the precision of time is 100ns.The facility is secondary developed with the GPS receiver that made by the special factory of United States. It can track 12 GPS satellites at the same time, and selects the best satellite automaticly for locating and timing.It outputs UTC time ,and the synchronous precision is 1~10ms.The BE-M-1-NTP is quite cost effective and high quality,its highest record of MTBF is 5 years.

Specifications:

- Receiving frequency:1575.42MHZ, it can track 8-12 GPS satellites at the same time.

- Antenna radio sentivity:-166dbw, with 30 metres wire. If the wire is not long enough, customer can prolong it by himself by selection of coaxial-cable that attenuation of 1.56GHZ is not more than 0.7db per metre, the attenuation of prolonged cable is not more than 5db.

- Time Accuracy: GPS100ns ,NTP: 1~10ms

- Capture time: from 20 seconds to 2 minutes(the outputs of synchronous clock are all isolated by photoelectricity coupling and output 60ns)

- Time code output: 1 channel of NTP/SNTP+1 channel of 1PPS+1 channel of RS-232.

- Low cost: Cost is just half of 1U size master clocks,very economical.

- GPS antenna & software free: We offer free 30m GPS cable with antenna and free NTP/SNTP software.

- Small size: Can be portable to anyware and can be mounted to any place.

- Low freigth cost: Because of small size and weight, the freight charge of it is just 50% of 1U size master clock.

Feature and Benefits:

- Accurate universal atomic clock reference.

- Supports all NTP/SNTP compatible devices.

- Ideal for power substations,oil & gas field,CCTV and DVR applications.

- Far lower cost than competing products.

- Ideal for closed or secure networks.

- Direct network interface for remote siting.

- Simple setup — one IP address.

- Automatic GPS lock and time sync.

- Extremely compact design(Dimension: 15.8x14.6x6.0CM)

- Indoor location (GPS antenna on a window).

- Integral watchdog for long-term reliable operation.

- Rack, wall mount.

- Work temperature: -20 to 75C.

- Very low power use.

- 2 years warranty and life long maintenance

The Difference between OCXO and TCXO Oscillators

A crystal oscillator is an electronic oscillator circuit that uses the mechanical reverberation of a vibrating crystal (typically a quartz crystal) to create an electrical signal with precise frequency. It is often used for stabilization applications, to help keep track of time, and to provide a stable clock signal for digital integrated circuits.

Environmental factors such as humidity, pressure, vibration and in particular, temperature, affect the precision of the crystal oscillator’s frequency. To limit their level of influence, modified crystal oscillators are offered. Two popular versions are the temperature-compensated crystal oscillator (TCXO — “XO” is the old acronym for “crystal oscillator”) and oven-controlled crystal oscillator (OCXO). Both offer excellent short-term stability, with limitations coming mostly from the electronic components that are included in the oscillator circuits, and affects brought on by aging of the crystal.

TCXO: A smart, affordable solution

TCXOs are used to provide a higher level of temperature stability than the standard crystal oscillator (XO). Power consumption is greater with the TCXO and the cost is more, too, but these matters are inconsequential when you consider the fact that it effectively addresses the aforementioned environmental factors, and delivers a much more reliable signal than a normal XO.

Due to their higher level of performance, you are likely to find TCXOs in many of today’s smart phones, GPS devices and other base station applications.

Design

TCXOs use an element known as a voltage-controlled crystal oscillator (VCXO). Included is a temperature sensor that — when the temperature changes — will apply a small correct voltage to a varactor, which then produces a frequency that is equal and opposite to the change in frequency produced by the temperature. This counterbalance-based circuitry allows the TCXO to continue to provide a stable frequency without being influenced by environmental factors.

Power consumption

TCXOs require a short warm-up period (normally 100ms, or sometimes longer depending on the unit’s design). The warm-up allows all of the components to reach thermal equilibrium and ensures that the device delivers a precise signal. Those worried about power consumption will be pleased to hear that power used during this stage is for the most part, nominal.

Calibration

To remove the affects of an aging crystal, TCXOs come with an external adjustment that enables the frequency to be reset periodically. Time between these calibration adjustments varies based upon the level of accuracy required, but average recommendations are every six months to a year. Shorter periods can be used if higher levels of accuracy are necessary.

It should be noted that making any other form of adjustment to the mechanical tuning of the TCXO (other than that which is approved by the manufacturer) can change the electrical tuning sensitivity in the TCXO’s design which, in turn, will cause it to under- or over-correct. Applying temperature compensation can be problematic, too, because the temperature coefficient of the crystal changes with temperature. These changes won’t be linear and will only result in complicating the design of the total compensation network.

OCXO: Higher price and bigger footprint, but a much better performance

OCXOs work on the theory that if you heat the crystal beyond a temperature which it would normally encounter in the working environment, then the temperature of the crystal can be maintained at a constant level (normally around 158–176°F, or 70–80°C), thus resulting in a far greater degree of frequency stability. This version of crystal oscillator is typically used with tasks that require precise frequency, such as controlling radio transmitter frequency, cellular base stations and military communications equipment.

Design

To ensure that that it is optimized for a higher internal operating temperature, the crystal used in an OCXO is typically made from a special cut (AT- or SC-cut). The “oven” that is used is a thermally-insulated enclosure that contains the crystal as well as the oscillator assembly, buffering circuitry and supply voltage regulation. A thermistor temperature sensor is used to control the power of the heater and ensure that a precise temperature within the oven is maintained constantly.

While having a precisely regulated, temperature controlled environment all but guarantees top tier performance of the crystal, one should keep in mind that having everything together in an enclosed oven-like unit means that an OCXO is physically larger than a TCXO. As such, it cannot be used in many of the TCXO-appropriate miniature applications.

Power consumption

A longer warm-up period is required when using an OCXO because the oven will only begin to operate once it hits a precise temperature (some OCXO heaters actually require about an Amp of power during this time). Additionally, the on-going heat supply that the “oven” is maintained at requires a considerable amount of power, too. Such a high level of power consumption means that an OCXO cannot be run solely on batteries.

Calibration

As with the TCXO, periodic calibrations are required every six months to a year. This is largely dependent upon the device’s design and requirements of the application for which it’s being used.

Bottom line

A summary of figures that both devices have to offer:

*Figures courtesy of "Tutorial Precision Frequency Generation Utilizing OCXO and Rubidium Atomic Standards with Applications for Commercial, Space, Military, and Challenging Environments IEEE Long Island Chapter March 18, 2004."

TCXOs are smaller and more economical than OCXOs. They are a terrific solution for portable units that necessitate a reasonably accurate source.

OCXOs, on the other hand, might be more expensive and come with a larger footprint, but the precision of their frequency signal can’t be beat. ■

Economical IEC-101/102/103/104/Modbus Gateway

Economical IEC-101/102/103/104/Modbus Gateway for Solar Power Plant Data Acquisition

The Gateway is designed for low-cost projects like PV,industrial automation and other projects that is sensitive to cost, the gateway has 1 Ethernet port and 2 Serial interfaces and support IEC101,IEC102,IEC103,IEC104,Modbus RTU protocols.

Technial Specifications:

• Freescalei.MX287 Applications Processors,454MHz128M DDR2 Memory

• 128M Nand Flash

• 1 Ethernet Ports

• 2 RS-232/485 Isolation Serial Ports

• GPRS Communication Interface

• Wall Mount

Others:

| System | |

| CPU | Freescalei.MX287 Applications Processors,454MHz |

| Memory | DDR2 128M |

| Flash |

128M Nand Flash SD Socket 32GB |

| Operating System | Linux 2.6.35.3 |

| LED | |

|

System:Power x1,RUN x1, Serial:TxD x2,RxD x2 |

|

| Others | RTC,Buzzer,Watchdog Timer,Reset Button,Console Port x1 |

| Serial Communication | |

| Console Port |

BOX 1*3*2.54 Connector x1(Inside) RS232 115200bps N,8,1 |

| Serial Port |

2 xRS-232/485 TB Interface Connector Auto Mode SensingRS-232 Signals:TxD,RxD,GND RS-485 Signals:485A(Data+),485B(Data-) |

| Protection | Built-in 15KV ESD Protection For All Signals, 2KV <span iCoupler Digital Isolation Protection |

| Network Communication | |

| LAN |

Auto-sensing 10/100Mbps x 1, RJ45 Build-in 1.5KV Magnetic Isolation Protection |

| Wireless communication |

GPRS Communication Interface Support China Mobile/China Unicom |

| Power Requirements | |

| Power Input | 9-36VDC |

| Power Consumption | |

| 5W@12VDC | |

| Mechanical | |

| Dimensions | 89(L)x121(W)x27(H) |

| Installation | Wall Mount |

| Environmental | |

| Operating Temperature |

-20-60℃ -40-80℃(Optional) |

| Storage Temperature | -40-80℃ |

| Regulatory Approvals and Warranty | |

| EMC |

GB/T 17626.2-2006 Class 4(ESD) GB/T 17626.4-2008 Class 4(EFT) GB/T 17626.5-2008 Class 4(SURGE) GB/T 17626.6-2008 Class 3(EMI) |

| Warranty | 2 Years |

Protective Relay Market to Grow 6.5% by 2021

The global protective relay market is projected to grow at a CAGR of 6.5% from 2016 to 2021, to reach USD 4.54 Billion by 2021. This growth can be attributed to the increase in transmission & distribution activities across the globe. Ongoing smart grid and substation automation projects are also expected to drive the market.

Protective relays are used by utilities and industries to protect expensive instruments such as transformers and motors. The relay senses abnormalities in operating conditions, such as over-current, over-voltage, reverse power flow, and over-and-under frequency, and trips the circuit breaker. Microprocessor and intelligent relays are being used extensively, as they are multi-functional and cost-effective compared to electromechanical relays.

In emerging economies such as China and India, the market is boosted by rapid industrialization and urbanization activities. The report segments the protective relay market on the basis of major end-user applications into industries, utilities, renewables, and marine. Utilities are estimated to constitute the largest market for protective relays, and held the largest market share in 2015.

Asia-Pacific is estimated to hold the largest market share, followed by North America and Europe. In terms of individual countries, the market is dominated by China. This can be attributed to the extensive electrical infrastructure upgradation and new transmission & distribution lines being installed in the country.

China held the largest share of the global protective relay market in 2015. Rapid economic growth in BRICS nations is expected to drive the protective relay market in these nations. Protective relays will likely be used extensively in the new electrical transmission & distribution networks of BRICS countries.

Scope of the Report:

By Voltage

By Protection Mechanism

By End-User

By Region

Companies Profiled:

ABB Ltd

Eaton

Fanox

GE Co.

Littelfuse, Inc.

Mitsubishi Electric Corp.

NR Electric Co. Ltd

Schneider Electric SA

Sel, Inc.

Siemens AG

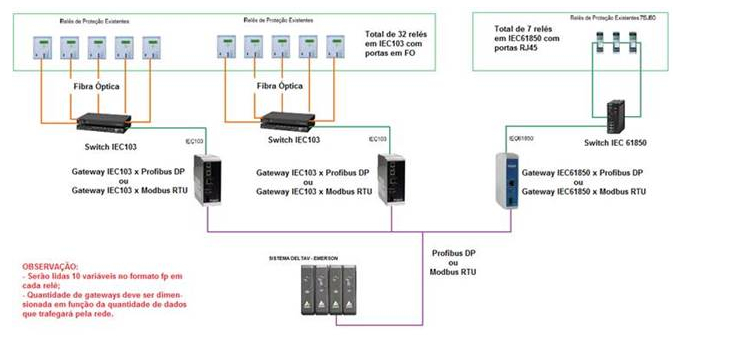

BE Offer Products and Solutions for Brazilian Power Substation

In this substation project,Bueno Electric's IEC61850 switch and BUE-801 IEC61850 gateway are applied.

BE-6000 Modbus I/O Modules in Indian Power Plant Project

BE-6000 Modbus I/O modules won the bid of Indian 4x600MW power plant project.The project uses our 4 channel Analogue I/O module to connect to the Master station in the DCS.

Difference between RTU and PLC

RTU and PLC products:

(1) the scope of applications:

RTU is mainly used in near field devices, so the RTU to working environment requirement general:

RTU environmental requirements:

Working temperature: - 40 degrees to 75 degrees

Storage temperature: - 40 degrees to 85 degrees

Relative humidity: 5% to 95%;

RTU products with reliable quality and features of the extreme working temperature of environment, suitable for all kinds of applications, all-weather not restricted by environment and geography,. 253

PLC to the environment requirement: 253

Working temperature: 0 to 55 degrees; 253

Storage temperature: - 40 degrees to 70 degrees;

Relative humidity: 5% to 95%;

PLC products is more suitable for the application of the indoor environment, a narrow temperature range.

(2). Communication protocol and flexibility

RTU products have more communication interface

RTU product usually have three to five or more communication interface, such as RS232, RS485, mainly ADAPTS to the field of all kinds of smart meters and all kinds of convenient access controller;

With support for multiple communication protocol MODBUS RTU products and DNP3 protocol;

Support new special protocol interface drive function. Can be connected with other different types of equipment, especially suitable for SCADA system application;

PLC communication interface and communication protocol is a single, suitable for relatively fixed and unified station control system.

(3) the RTU function

RTU in applications in addition to some of the most basic similar functions and PLC for some industry more proprietary technology, has some industry special functions, such as gas RTU have AGA algorithm, the wellhead RTU has the special control algorithm, etc. For small sites, both about the same, the application scope of RTU series has the storage space, greater than the PLC, in addition, the RTU using built-in flow calculation program, can replace the flow computer, directly used for measurement, the historical record storage, etc.

In configuration points, both in terms of analog, RTU is slightly better than a PLC; RTU is mainly for field application environment Settings, the requirement of environment than PLC series more broad. From the point of memory space and the supplementary function, RTU is superior to the PLC. Environment is a good place for site, PLC will be more economical; To use environment on site is poor, such as the oil industry of irrigation area monitoring, gas pipelines, oil and gas well site monitoring, municipal pipe network, and many other outdoor environmental factors using RTU products are more appropriate. Together two kinds of products, each has its features and characteristics, and is aimed at the application scope of also is not the same.